Air or gas spaces in refractory walls

Air or gas spaces in refractory walls

SIMU-THERM simulates three heat transfer effects in cavities

- thermal radiation across the cavity

- circular gas convection

- conduction due to thermal conductivity of the gas

In SIMU-THERM static gaps (=enclosed cavities, no entry for fresh air) may contain

- ambient air

- gas with given components (e.g. with hydrogen)

- gas or air pressure from vacuum to reactor pressure

SIMU-THERM can simulate continuous air flow under protection shrouds or other air spaces with inflow and outflow of ambient air. Air flow can be forced or driven by thermal air uplift. SIMU-THERM treats the air gap as a special kind of wall layer. The surface temperatures on both sides of the gap and the air outflow temperature are calculated.

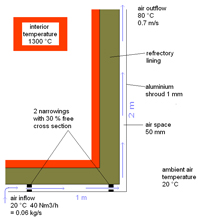

Air flow sample 1

Contact protection shroud around a furnace part. Air flow driven by natural convection (thermal uplift)

Contact protection shroud around a furnace part. Air flow driven by natural convection (thermal uplift)

In order to optimize the temperature of the protection shroud, the width of the air space can be varied easily because it is just one of the wall layers.

Air temperature and shroud temperature are shown for the air entry, air outlet and for the middle of the flow path.

The flow velocity is decelerated by two beams narrowing the available cross section .

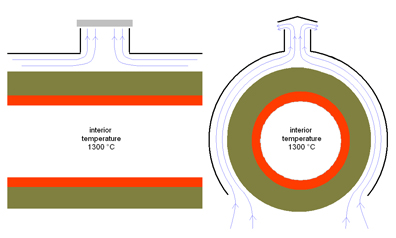

Air flow sample 2

Rain protection shroud around a transportation tube for hot gas.

In SIMU-THERM a separate heat loss calculation is made for the covered part of the tube. The flow velocity is decelerated by the fact that the cross section of the outlet is smaller than the cross section of the two branches of the air space around the tube.

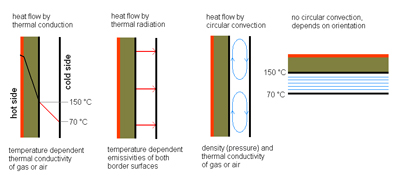

Static air or gas spaces

A heat loss calculation in SIMU-THERM may contain several layers formed by static gaps filled with air or other gas. The pressure of air or gas is an input parameter The composition of the gas is chosen from 10 standard components. In wide gaps and low pressure the major heat transportation comes from thermal radiation, depending on the surface emissivities on both sides of the gap. Normally the emissivities are static input values. If a wide temperature range is covered, e.g. for high temperature radiation sheet insulation, emissivities can be given as temperature dependent curves.

In case of high gas pressure and large share of hydrogen in the gas the circular convection in the gas space can contribute the largest part of heat transportation. A factor for the circular convection can be input according to the location in space.

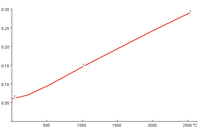

Static air space sample 1

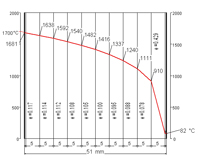

Emissivity of polished

molybdenum from

0 °C to 2500 °C

Thermal insulation of a vacuum furnace consisting of 10 vacuum spaces (each 5 mm) between polished molybdenum sheets. Heat bridges not included. The air space at the water cooled side has a significantly higher thermal resistance because the emissivity of molybdenum is very low at 82 °C (=surface temperature). If available, several emissivity curves of a metal (e.g. polished, sand blasted, oxidized) can be stored in the material data base. For both sides of an air gap one of the emissivity curves of the bordering materials can be selected.