SIMU-THERM News

Privacy Policy / Datenschutzerklärung

Privacy Policy

Personal data (usually referred to just as "data" below) will only be processed by us to the extent necessary and for the purpose of providing a functional and user-friendly website, including its contents, and the services offered there.

Per Art. 4 No. 1 of Regulation (EU) 2016/679, i.e. the General Data Protection Regulation (hereinafter referred to as the "GDPR"), "processing" refers to any operation or set of operations such as collection, recording, organization, structuring, storage, adaptation, alteration, retrieval, consultation, use, disclosure by transmission, dissemination, or otherwise making available, alignment, or combination, restriction, erasure, or destruction performed on personal data, whether by automated means or not.

The following privacy policy is intended to inform you in particular about the type, scope, purpose, duration, and legal basis for the processing of such data either under our own control or in conjunction with others. We also inform you below about the third-party components we use to optimize our website and improve the user experience which may result in said third parties also processing data they collect and control.

Our privacy policy is structured as follows:

I. Information about us as controllers of your data

II. The rights of users and data subjects

III. Information about the data processing

I. Information about us as controllers of your data

The party responsible for this website (the "controller") for purposes of data protection law is:

Dr. Hilger & Daniel Software GmbH

Weilerstraße 44

50321 Brühl

Germany

Telephone: (49) 02232 925228

Email:

This email address is being protected from spambots. You need JavaScript enabled to view it.

Legal Representative:

Rudolf Daniel

II. The rights of users and data subjects

With regard to the data processing to be described in more detail below, users and data subjects have the right

- to confirmation of whether data concerning them is being processed, information about the data being processed, further information about the nature of the data processing, and copies of the data (cf. also Art. 15 GDPR);

- to correct or complete incorrect or incomplete data (cf. also Art. 16 GDPR);

- to the immediate deletion of data concerning them (cf. also Art. 17 DSGVO), or, alternatively, if further processing is necessary as stipulated in Art. 17 Para. 3 GDPR, to restrict said processing per Art. 18 GDPR;

- to receive copies of the data concerning them and/or provided by them and to have the same transmitted to other providers/controllers (cf. also Art. 20 GDPR);

- to file complaints with the supervisory authority if they believe that data concerning them is being processed by the controller in breach of data protection provisions (see also Art. 77 GDPR).

In addition, the controller is obliged to inform all recipients to whom it discloses data of any such corrections, deletions, or restrictions placed on processing the same per Art. 16, 17 Para. 1, 18 GDPR. However, this obligation does not apply if such notification is impossible or involves a disproportionate effort. Nevertheless, users have a right to information about these recipients.

Likewise, under Art. 21 GDPR, users and data subjects have the right to object to the controller's future processing of their data pursuant to Art. 6 Para. 1 lit. f) GDPR. In particular, an objection to data processing for the purpose of direct advertising is permissible.

III. Information about the data processing

Your data processed when using our website will be deleted or blocked as soon as the purpose for its storage ceases to apply, provided the deletion of the same is not in breach of any statutory storage obligations or unless otherwise stipulated below.

Server data

For technical reasons, the following data sent by your internet browser to us or to our server provider will be collected, especially to ensure a secure and stable website: These server log files record the type and version of your browser, operating system, the website from which you came (referrer URL), the webpages on our site visited, the date and time of your visit, as well as the IP address from which you visited our site.

The data thus collected will be temporarily stored, but not in association with any other of your data.

The basis for this storage is Art. 6 Para. 1 lit. f) GDPR. Our legitimate interest lies in the improvement, stability, functionality, and security of our website.

The data will be deleted within no more than seven days, unless continued storage is required for evidentiary purposes. In which case, all or part of the data will be excluded from deletion until the investigation of the relevant incident is finally resolved.

Model Data Protection Statement for Anwaltskanzlei Weiß & Partner

Datenschutzerklärung

Personenbezogene Daten (nachfolgend zumeist nur „Daten“ genannt) werden von uns nur im Rahmen der Erforderlichkeit sowie zum Zwecke der Bereitstellung eines funktionsfähigen und nutzerfreundlichen Internetauftritts, inklusive seiner Inhalte und der dort angebotenen Leistungen, verarbeitet.

Gemäß Art. 4 Ziffer 1. der Verordnung (EU) 2016/679, also der Datenschutz-Grundverordnung (nachfolgend nur „DSGVO“ genannt), gilt als „Verarbeitung“ jeder mit oder ohne Hilfe automatisierter Verfahren ausgeführter Vorgang oder jede solche Vorgangsreihe im Zusammenhang mit personenbezogenen Daten, wie das Erheben, das Erfassen, die Organisation, das Ordnen, die Speicherung, die Anpassung oder Veränderung, das Auslesen, das Abfragen, die Verwendung, die Offenlegung durch Übermittlung, Verbreitung oder eine andere Form der Bereitstellung, den Abgleich oder die Verknüpfung, die Einschränkung, das Löschen oder die Vernichtung.

Mit der nachfolgenden Datenschutzerklärung informieren wir Sie insbesondere über Art, Umfang, Zweck, Dauer und Rechtsgrundlage der Verarbeitung personenbezogener Daten, soweit wir entweder allein oder gemeinsam mit anderen über die Zwecke und Mittel der Verarbeitung entscheiden. Zudem informieren wir Sie nachfolgend über die von uns zu Optimierungszwecken sowie zur Steigerung der Nutzungsqualität eingesetzten Fremdkomponenten, soweit hierdurch Dritte Daten in wiederum eigener Verantwortung verarbeiten.

Unsere Datenschutzerklärung ist wie folgt gegliedert:

I. Informationen über uns als Verantwortliche

II. Rechte der Nutzer und Betroffenen

III. Informationen zur Datenverarbeitung

I. Informationen über uns als Verantwortliche

Verantwortlicher Anbieter dieses Internetauftritts im datenschutzrechtlichen Sinne ist:

Dr. Hilger & Daniel GmbH

Weilerstraße 44

50321 Brühl

Deutschland

Telefon: (49) 02232 925228

E-Mail:

This email address is being protected from spambots. You need JavaScript enabled to view it.

Gesetzlicher Vertreter:

Rudolf Daniel

II. Rechte der Nutzer und Betroffenen

Mit Blick auf die nachfolgend noch näher beschriebene Datenverarbeitung haben die Nutzer und Betroffenen das Recht

- auf Bestätigung, ob sie betreffende Daten verarbeitet werden, auf Auskunft über die verarbeiteten Daten, auf weitere Informationen über die Datenverarbeitung sowie auf Kopien der Daten (vgl. auch Art. 15 DSGVO);

- auf Berichtigung oder Vervollständigung unrichtiger bzw. unvollständiger Daten (vgl. auch Art. 16 DSGVO);

- auf unverzügliche Löschung der sie betreffenden Daten (vgl. auch Art. 17 DSGVO), oder, alternativ, soweit eine weitere Verarbeitung gemäß Art. 17 Abs. 3 DSGVO erforderlich ist, auf Einschränkung der Verarbeitung nach Maßgabe von Art. 18 DSGVO;

- auf Erhalt der sie betreffenden und von ihnen bereitgestellten Daten und auf Übermittlung dieser Daten an andere Anbieter/Verantwortliche (vgl. auch Art. 20 DSGVO);

- auf Beschwerde gegenüber der Aufsichtsbehörde, sofern sie der Ansicht sind, dass die sie betreffenden Daten durch den Anbieter unter Verstoß gegen datenschutzrechtliche Bestimmungen verarbeitet werden (vgl. auch Art. 77 DSGVO).

Darüber hinaus ist der Anbieter dazu verpflichtet, alle Empfänger, denen gegenüber Daten durch den Anbieter offengelegt worden sind, über jedwede Berichtigung oder Löschung von Daten oder die Einschränkung der Verarbeitung, die aufgrund der Artikel 16, 17 Abs. 1, 18 DSGVO erfolgt, zu unterrichten. Diese Verpflichtung besteht jedoch nicht, soweit diese Mitteilung unmöglich oder mit einem unverhältnismäßigen Aufwand verbunden ist. Unbeschadet dessen hat der Nutzer ein Recht auf Auskunft über diese Empfänger.

Ebenfalls haben die Nutzer und Betroffenen nach Art. 21 DSGVO das Recht auf Widerspruch gegen die künftige Verarbeitung der sie betreffenden Daten, sofern die Daten durch den Anbieter nach Maßgabe von Art. 6 Abs. 1 lit. f) DSGVO verarbeitet werden. Insbesondere ist ein Widerspruch gegen die Datenverarbeitung zum Zwecke der Direktwerbung statthaft.

III. Informationen zur Datenverarbeitung

Ihre bei Nutzung unseres Internetauftritts verarbeiteten Daten werden gelöscht oder gesperrt, sobald der Zweck der Speicherung entfällt, der Löschung der Daten keine gesetzlichen Aufbewahrungspflichten entgegenstehen und nachfolgend keine anderslautenden Angaben zu einzelnen Verarbeitungsverfahren gemacht werden.

Serverdaten

Aus technischen Gründen, insbesondere zur Gewährleistung eines sicheren und stabilen Internetauftritts, werden Daten durch Ihren Internet-Browser an uns bzw. an unseren Webspace-Provider übermittelt. Mit diesen sog. Server-Logfiles werden u.a. Typ und Version Ihres Internetbrowsers, das Betriebssystem, die Website, von der aus Sie auf unseren Internetauftritt gewechselt haben (Referrer URL), die Website(s) unseres Internetauftritts, die Sie besuchen, Datum und Uhrzeit des jeweiligen Zugriffs sowie die IP-Adresse des Internetanschlusses, von dem aus die Nutzung unseres Internetauftritts erfolgt, erhoben.

Diese so erhobenen Daten werden vorübergehend gespeichert, dies jedoch nicht gemeinsam mit anderen Daten von Ihnen.

Diese Speicherung erfolgt auf der Rechtsgrundlage von Art. 6 Abs. 1 lit. f) DSGVO. Unser berechtigtes Interesse liegt in der Verbesserung, Stabilität, Funktionalität und Sicherheit unseres Internetauftritts.

Die Daten werden spätestens nach sieben Tage wieder gelöscht, soweit keine weitere Aufbewahrung zu Beweiszwecken erforderlich ist. Andernfalls sind die Daten bis zur endgültigen Klärung eines Vorfalls ganz oder teilweise von der Löschung ausgenommen.

Muster-Datenschutzerklärung der Anwaltskanzlei Weiß & Partner

Demo version

Email us at

This email address is being protected from spambots. You need JavaScript enabled to view it.

to request a demo version of our software!

You can request a fully-functional time-limited trial version of Simu-Therm 7.1 including the Transient expansion

Calculation projects

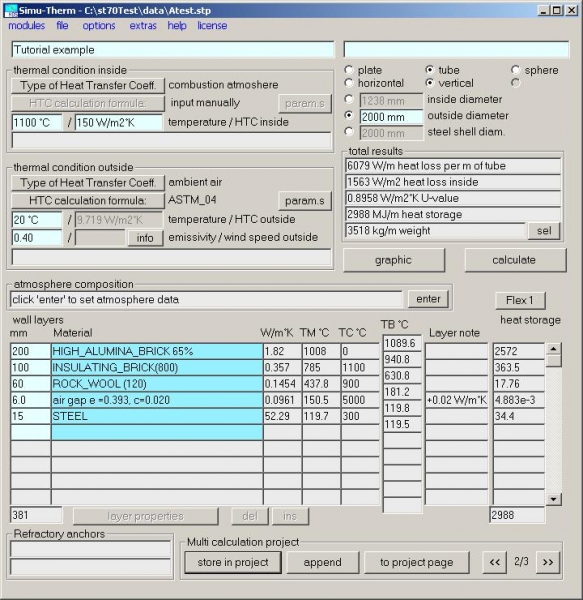

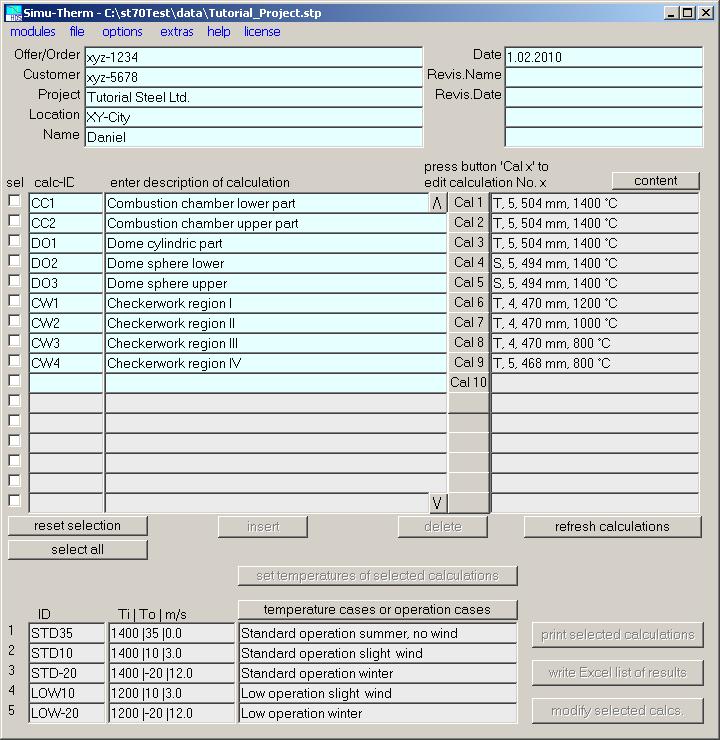

Multi-calculation projects in Simu-Therm 7.0

Project files

In Simu-Therm 7.0 steady state heat loss calculations belonging to a construction project are collected and processed in multi-calculation a project work file. The calculations in the project file can be managed, printed and modified together or in subsets.

Modification of calculations comprises:

- Switching of temperature and other conditions in the hot and cold face

- Switching of tube diameter

- Search and replace materials.

- Search and replace text

- Search and replace atmospheres

Additionally ambient cases (e.g. summer/winter) and operation cases (e.g. high/low inside temperature) can be defined and applied to the calculations.

Overview in Excel sheets

Results of multi-calculations can be listed into files readable by MS Excel or other spreadsheet programs.

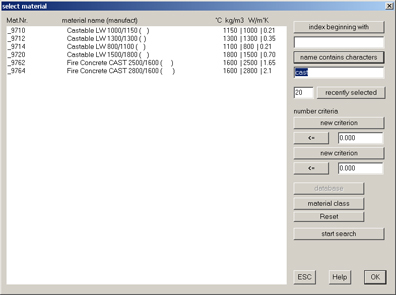

material management

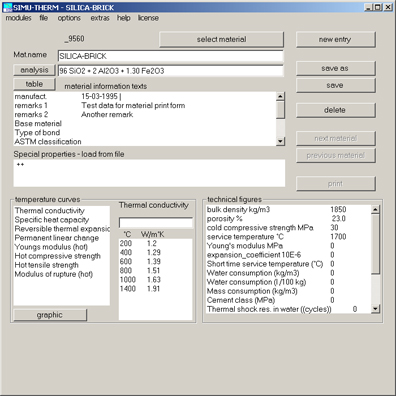

The material management module in SIMU-THERM 6.5Material mangement - main dialog

New materials can be inserted with ‘new entry’

All of the attributes in the listboxes ‘material information texts’, ‘temperature curves’ and ‘technical figures’ are user-defined. Here you see the standard attributes predefined in SIMU-THERM 6.0

Material mangement - main dialog

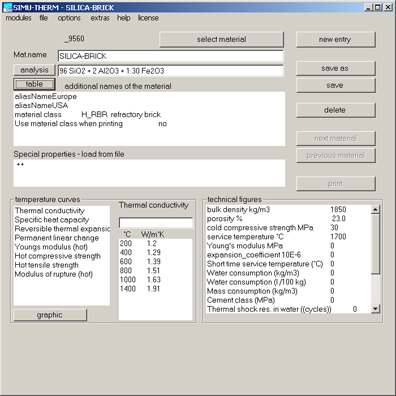

Again the main dialog, with the text listbox switched to ‘additional names of the material’

Alias names for the use in printouts can be defined.

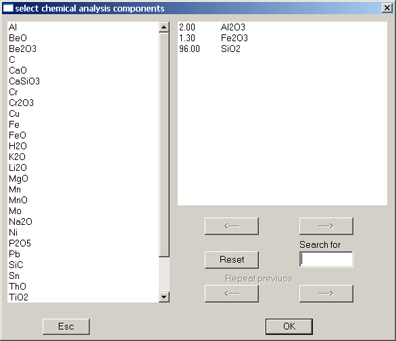

The dialog for chemical analysis

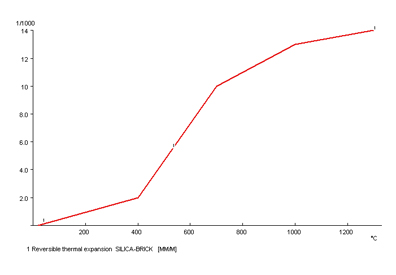

The temperature dependent attributes can be shown in a graph

This is a nonlinear thermal expansion in mm/m over the temperature

Basic progam modules

simu-therm consists of the following basic program modules:transient simulation

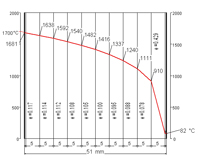

Transient heat flow simulation in SIMU-THERM 7.1

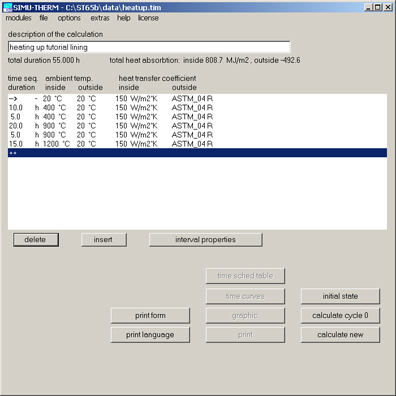

Transient simulation - main dialog

Heating schedule - total duration 55 hours

The ambient temperatures inside and outside are not constant (unlike in steady state)

They are given as curves over the time. The same holds for the heat transition coefficients.

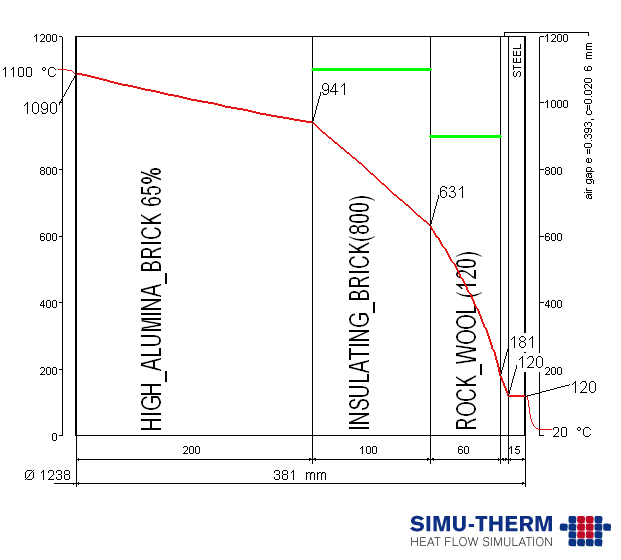

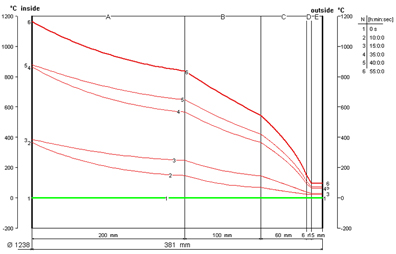

Temperature profiles in the wall at different times

Green line: Initial temperature (cold)

Fat red line: Final temperature

Thin red lines: intermediate times

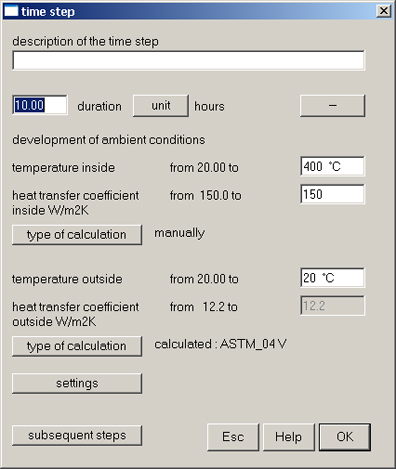

Time interval dialog

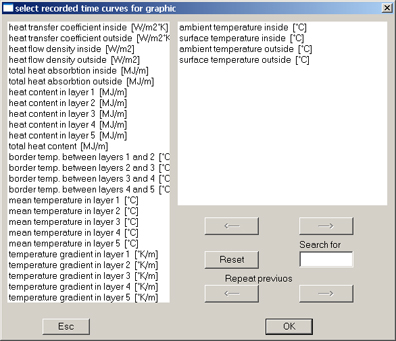

Selection dialog for time curves

One or more figures recorded during the simulation are chosen for a graph over the time.

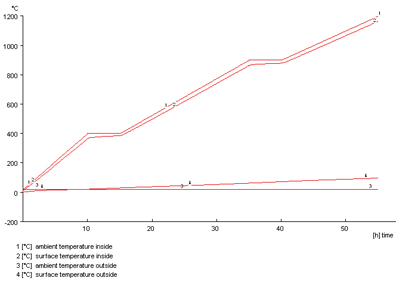

Time curves graph 1

Here the following figures have been selected:

• Ambient temperature (= temperature defined in the heating schedule)

• Surface temperature inside

• Two of the temperature between wall layers

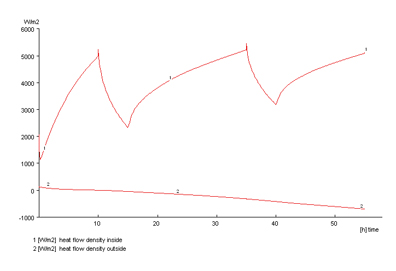

Time curves graph 2

Here the following figures have been selected:

• Heat flow density inside W/m2 (= heat absorbed by the wall)

• Heat flow density outside W/m2 (= heat loss of the wall to ambient air)

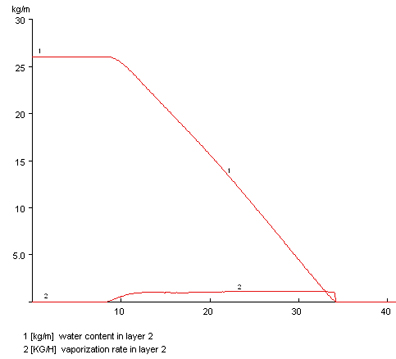

Time curves graph 3

Here the following figures have been selected:

• Water content [kg] in layer 2

• Vaporization rate [kg/h] in layer 2

Layer 2 is dry after about 34 hours. The water is vaporized almost regularly.

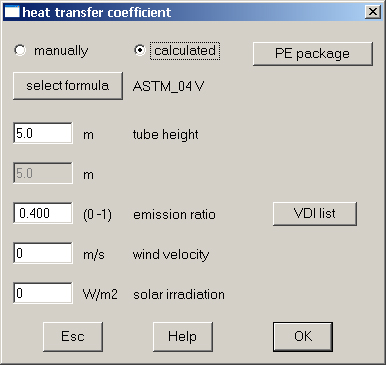

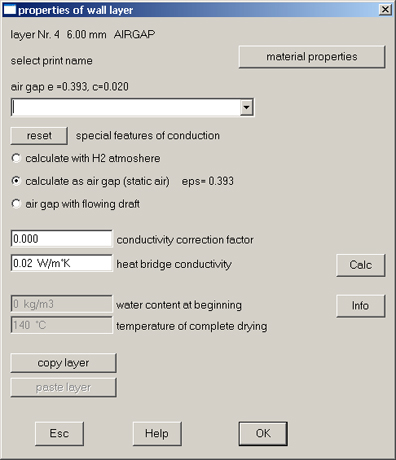

useful features for steady state calculation

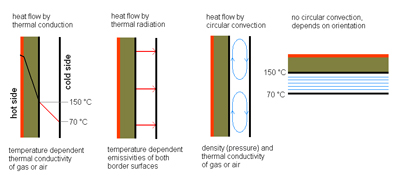

heat transfer coefficient both with ASTM old and release 2004air gap with static air

air gap with air flow

gas filed caves with H2 and high pressure

Why SIMU-THERM for you ?

Covering a wide range of applications

SIMU-THERM offers a lot of useful features for the high temperature technology.

• Convenient handling of multi-calculation projects. Easy changing of materials, diametes, ambient and operation conditions for all calculations of a project in one step

• air space layers with air flow or gas-filled

• transient simulation: absolutely stable, no mathematical knowledge necessary

• transient simulation of drying of fire concretes

• simulation of special heating conditions

Flexible and open software

SIMU-THERM admits a maximum of independence. E.g. print forms: You can arrange the print layout according to your needs, use different layouts for different customers and each layout in different print languages.

Moreover you can easily create a printout in another languge.

Highly innovative

We include new features into our software responding to technical progress in refractory design in close contact to our customers. We continuously adapt useful developments in computer technology to your convenience.

Competent advisory service for your applications

Experience has shown that SIMU-THERM’s self explaining user interface enables new users to accomplish steady state calculations without training. We support your start in advanced calculations, e.g. transient simulation by offering advice for your concrete application.

What is SIMU-THERM ?

SIMU-THERM is a heat transfer calculation software developed for refractory design.Due to the precise mathematical modelling of the heat transfer process it is also appropriate for all kinds of high temperature applications. The initial program was written in 1989-/90based on the author’s experience in refractory design and thermal computation.Today it is improved continually in close contact with renowned companies using SIMU-THERM every day.

SIMU-THERM 7.1 is a self explaining Windows program. Thus it is suitable for occasional users as well as fast working experienced users. SIMU-THERM’s print forms can be adapted to the user’s corporate layout.

Adaption of logos, comments etc. is included in delivery and can be modified easily later by the user The software is available in English and German. The documentation is available in English only.

Requirements

Unlike earlier versions SIMU-THERM 6.5 and higher is independent of MS Office. Acrobat Reader is necessary for using the PDF documentation.

The SIMU-THERM “philosophy“

There used to be no possibility of performing advanced thermal calculations for a refractory engineer because no affordable software was available.

Thus SIMU-THERM is dedicated to these goals:

- Deliver high quality software for advanced thermal calculation

at reasonable prices - Simplifying the handling of this software in order to allow the common

usage of these methods

Even the first release of SIMU-THERM in 1990 (for MS DOS) included transient calculation and a comfortable dialog based user interface. Today the Finite Element interface enables the user to perform multidimensional computations within 15 minutes.

The present module structure

Today SIMU-THERM consists of a basic program and several expansion modules. The base program is a high end heat transfer program allowing steady state and transient calculations.

Features of the base program:

- Steady state and transient calculation up to 30 wall layers

- Heat transfer coefficients calculated according to ASTM680 (1986 and 2004), VDI heat atlas.

- Air gap layers: calculation for static air and free or forced air flow. Calculation includes the heat transfer across the gap by thermal radiation.

- Impact of combustion atmosphere and heat bridges on heat conductivity

- Material management system in including a collection of basic refractory material classes.

Easy input and retrieval of your own materials.

Supports the use of alias names and multilingual names for materials. - Print forms can easily be altered. 4 predefined print forms, each in printable English, German, French, Italian, Spanish. More languages are easy to add.

The expansion modules can be added to the base program in any order. They provide advanced calculation methods for different purposes.

Impressum

Hilger & Daniel Software GmbH

Weilerstr. 44

D 50321 Bruehl

Tel (49) 02232 925228

Fax (49) 02232 925229

mail:

This email address is being protected from spambots. You need JavaScript enabled to view it.

Geschäftsführer:

Dipl. Ing. Dr. Stefan Hilger

Dipl. Math. Rudolf Daniel

Handelsregister: HRB 43648

Gerichtsstand Köln

Umsatzsteuer-ID-Nr.:

DE 123492915

Verantwortlicher für journalistisch-redaktionelle gestaltete Inhalte:

Daniel, Rudolf

Weilerstraße 44

50321 Brühl

E-Mail:

This email address is being protected from spambots. You need JavaScript enabled to view it.

Alle Rechte vorbehalten. Texte Bilder, Grafiken, Sound, Animationen und Videos unterliegen dem Schutz des Urheberrechts und anderer Schutzgesetze. Der Inhalt dieser Website darf nicht zu kommerziellen Zwecke verbreitet oder Dritten zugänglich gemacht werden. Irrtürmer und Änderungen vorbehalten. Sollten wir auf diesen Seiten Verknüpfungen zu anderen Seiten im Internet angelegt haben, so haben wir auf sämtliche Links keinerlei Einfluss. Deshalb distanzieren wir uns hiermit ausdrücklich von allen Inhalten der verknüpften Seiten. Diese Erklärung gilt für alle auf dieser Site ausgebrachten Links und für alle Inhalte der Seiten, zu denen ggf. Banner führen.

Konzeption, grafische Umsetzung und Realisierung der Internetseite:

mbm Computer e.K.

Bahnhofstrasse 9

50321 Brühl

Inhaber: Frank Müller

Tel.: 0 22 32 / 969 38 0

Fax: 0 22 32 / 969 38 99

www.mbm-medienwerkstatt.de

This email address is being protected from spambots. You need JavaScript enabled to view it.

About Us

| Since: | 1990 |

| Business: | Thermal simulation software for high temperature applications, refractory design, plant engineering |

| Team: | Dipl. Ing. Dr. Stefan Hilger Dipl. Math. Rudolf Daniel |

| Products | Heat transfer simulation software SIMU-THERM for Windows Advanced steady state and transient simulation of heat transfer Transient heating, drying of fire concrete, tensions in refractory lining |

| Service | Thermal calculations for high temperature processes Multidimensional computation with Finite Element software |

Steady state calculation

Transient expansion module

In version Simu-Therm 7.1 the transient simulation module includes the following expansion modules:

Languages

The following languages are supported by simutherm | English |  | Deutsch |  | Francais | |||

| Italiano |  | Espanol |

PE Process Engineering package

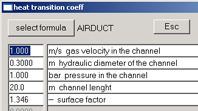

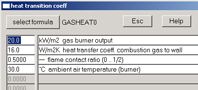

PE Process Engineering expansionThis expansion provides simulation of special heat transfer conditions both on the hot and cold side.

It is based on a formula interface intended to add easily calculation formulas for heat transfer coeffi-cients. The calculation is bases on an individual set of parameters for each of the formulas. In this way the software can be customized to new requirements without changes in the core parts of the calculation algorithms. All formulas can be used in steady state and in transient simulation.

In SIMU-THERM 6.5 the following heat transfer calculation are available:

AIRDUCT – convective heat transfer in air channel

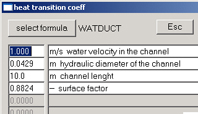

WATDUCT – convective heat transfer in water channel

WATFILM – convective heat transfer under a falling water film

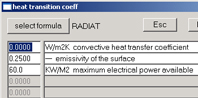

RADIAT – thermal radiation plus a fixed convective component

GASHEAT0 – heating with limited burner capacity, flame temperature known

GASHEAT – heating with limited burner capacity, gas exit temperature known

GASCOOL – cooling with a small air flow on the hot face

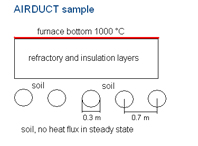

AIRDUCT application sample

|  |

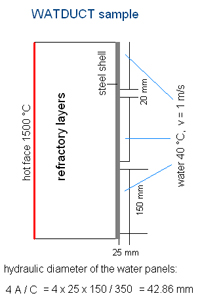

WATDUCT application sample

|  |

In the panels water of 50 °C is flowing with velocity

1 m/s. The length of the water flow is 10 m.

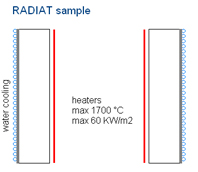

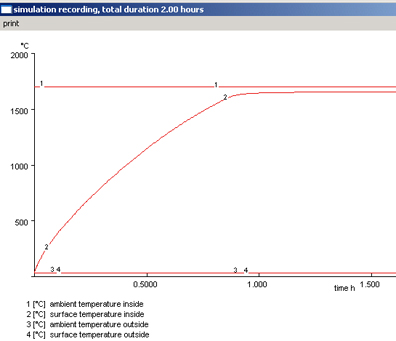

RADIAT application sample

|  |

Simulation result: the maximum inside temperature is reached after about 1 hour.

GASHEAT application sample

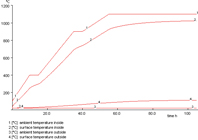

|  |

Heating up a furnace is performed with 20 kW gas burner capacity per square meter wall.

Due to the limitation of the burner capacity, there is a large difference between the flame tempera-ture and the surface temperature. Note that the curve of the inside surface temperature has become very smooth.

Air or gas spaces in refractory walls

Air or gas spaces in refractory walls

SIMU-THERM simulates three heat transfer effects in cavities

- thermal radiation across the cavity

- circular gas convection

- conduction due to thermal conductivity of the gas

In SIMU-THERM static gaps (=enclosed cavities, no entry for fresh air) may contain

- ambient air

- gas with given components (e.g. with hydrogen)

- gas or air pressure from vacuum to reactor pressure

SIMU-THERM can simulate continuous air flow under protection shrouds or other air spaces with inflow and outflow of ambient air. Air flow can be forced or driven by thermal air uplift. SIMU-THERM treats the air gap as a special kind of wall layer. The surface temperatures on both sides of the gap and the air outflow temperature are calculated.

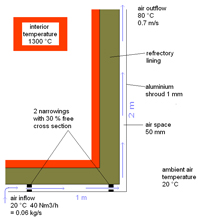

Air flow sample 1

Contact protection shroud around a furnace part. Air flow driven by natural convection (thermal uplift)

Contact protection shroud around a furnace part. Air flow driven by natural convection (thermal uplift)

In order to optimize the temperature of the protection shroud, the width of the air space can be varied easily because it is just one of the wall layers.

Air temperature and shroud temperature are shown for the air entry, air outlet and for the middle of the flow path.

The flow velocity is decelerated by two beams narrowing the available cross section .

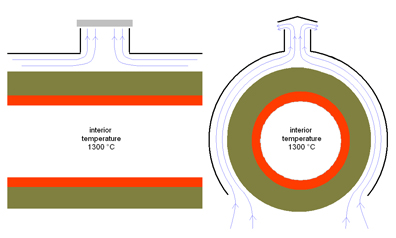

Air flow sample 2

Rain protection shroud around a transportation tube for hot gas.

In SIMU-THERM a separate heat loss calculation is made for the covered part of the tube. The flow velocity is decelerated by the fact that the cross section of the outlet is smaller than the cross section of the two branches of the air space around the tube.

Static air or gas spaces

A heat loss calculation in SIMU-THERM may contain several layers formed by static gaps filled with air or other gas. The pressure of air or gas is an input parameter The composition of the gas is chosen from 10 standard components. In wide gaps and low pressure the major heat transportation comes from thermal radiation, depending on the surface emissivities on both sides of the gap. Normally the emissivities are static input values. If a wide temperature range is covered, e.g. for high temperature radiation sheet insulation, emissivities can be given as temperature dependent curves.

In case of high gas pressure and large share of hydrogen in the gas the circular convection in the gas space can contribute the largest part of heat transportation. A factor for the circular convection can be input according to the location in space.

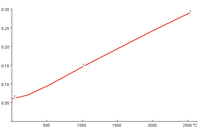

Static air space sample 1

Emissivity of polished

molybdenum from

0 °C to 2500 °C

Thermal insulation of a vacuum furnace consisting of 10 vacuum spaces (each 5 mm) between polished molybdenum sheets. Heat bridges not included. The air space at the water cooled side has a significantly higher thermal resistance because the emissivity of molybdenum is very low at 82 °C (=surface temperature). If available, several emissivity curves of a metal (e.g. polished, sand blasted, oxidized) can be stored in the material data base. For both sides of an air gap one of the emissivity curves of the bordering materials can be selected.

Prices

Please have a look at the current price list valid until 31/12/2020

Prices for educational licenses on request

View Pricelist (PDF)

Training and Service

Services (prices on request):

- Adapt MS Excel and MS Access interfaces to import material data from the customer's data base in Excel. Access or other SQL data bases

- Create SIMU-THERM print forms as determined by the customer

- Create material databases from producer's datasheets of current refractory materials.

- Perform calculations

Training:

Extensive tutorial material is available on request, showing how to use the program with step-by-step, realistic sample calculations.

How To Buy Simu-Therm

Place an order

Simu-Therm cannot be bought online, because it is licensed individually for each customer. For this we need name and address of your company and, if you are resident in the European Union, the valid VAT-ID of the company.

If you intend to buy Simu-Therm, please just advise in an email which modules and the number of licenses you want, and include the company data as mentioned.

Payment

Bank transfer is preferred, cheque is also possible. Invoice is issued in printable PDF file or by post, if required

Delivery and license

Simu-Therm is delivered by download after receiving the order. You get a download link and an individual license file to run the software. The license file contains and displays the address of your company. The license doesn't expire and doesn't need to be renewed annually.

Upgrades

The price of an upgrade is calculated individually:

Upgrade price = Catalog price - Remaining residual value of earlier licenses

The residual value is decreased 7.5% for every year of software use.

Example:

If you upgrade after 3 years without changing the software configuration, the residual value is

0.925 x 0.925 x 0.925 = 0.791 = 79.1 %.

Then the upgrade price is 100 - 79.1 = 20.9%